with spare parts sales or

technical customer support

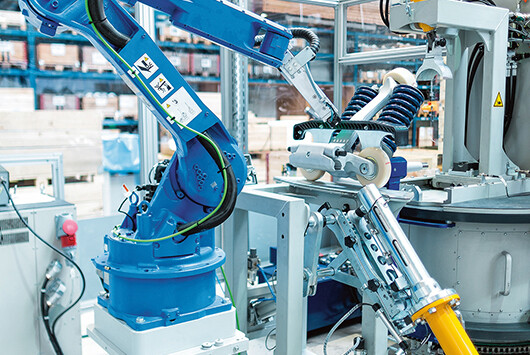

Doppelmayr Customer Support provides comprehensive know-how on the whole spectrum of rope-propelled transport systems and develops the ideal solution to suit your needs. Your success is our success. The customer support team responds quickly, thinks long term and offers you the optimal benefits of availability and operational safety and reliability, enabling you to concentrate on your core business.

Carrier adjustments

Adjustments to mechanical equipment in the stations (rope alignment, grip opening and closing lines, safety devices, etc.)

Adjustment and alignment of line structures

Inspection and adjustment of the rope in the area of the station entrance and exit and in the stations, when stationary and when running

Inspection of rope twist

Inspection and adjustment of the guide rail in the area of the station entrance and exit

Inspection and horizontal and vertical adjustment of the outer guide rail

Inspection and adjustment of the grip opening and closing lines

Documentation and issue of the grip opening and closing line report in accordance with applicable standards

Removal

Shipment to subsupplier

Installation including adjustment work

Bleeding of brake systems

Visual inspection for surface flaws, deformation, wear and corrosion

Inspection of settings and components

Function testing

Inspection documentation in accordance with applicable standards

Function check and inspection of the hydraulic system

Cleaning, filtering or oil change for the entire hydraulic system

Inspection for internal and external leakage of the hydraulic components

Replacement of wear parts with Doppelmayr spare parts

Records and documentation of the work performed in accordance with applicable standards

Removal

Cost effectiveness analysis

Disassembly and cleaning of individual parts

Visual inspection for surface flaws, deformation, wear and corrosion

Magnetic particle testing of axles for wear

Replacement of wear parts with Doppelmayr spare parts

Verification of required grip force

Inspection documentation in accordance with applicable standards

You benefit from the included magnetic particle testing of the axles in collaboration with the accredited test center

Removal of the sheave assembly

Disassembly and cleaning of components

Visual inspection for surface flaws, deformation, wear and corrosion

Magnetic particle testing of the axles for surface flaws

Inspection of Glacier bushings and axles for wear

Replacement of wear parts with Doppelmayr spare parts

Grease lubrication

Removal of fretting corrosion

Installation of inspected sheave assemblies

Adjustment of sheave assemblies

Inspection of rope tracking and alignment of sheave assemblies

Documentation in accordance with applicable standards

Visual inspection followed by electromagnetic testing including full documentation

Rope shortening

Splice repair

Detensioning of the rope

Removal of bullwheel

Bearing replacement including measurement to check bearing seat

Visual inspection of support hub for surface flaws, deformation, wear and corrosion

Magnetic particle testing of the support hub for surface flaws

Replacement of wear parts with original spare parts

Installation of components including system lubrication and test run

Records and documentation of the work performed in accordance with applicable standards

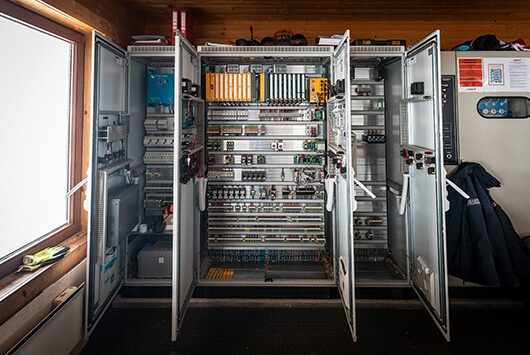

Electrotechnical inspection and service

Electrotechnical troubleshooting (optionally by means of remote maintenance)

Fault diagnosis for electrotechnical components

Repair of electrotechnical components

Records and documentation in accordance with applicable standards

Bearing and bushing tool

Bullwheel liner assembly fixture

Bullwheel liner milling tool

Anchor bolt pretensioning device

Oil filter unit

Grip roller bearing replacement tool

Suspension carrier for grips

Many years of experience

Inspected by our experts

Clarity on the technical status of your installation

Recommendations for increasing the lifetime

Preventing unnecessary wear

Ensuring optimized operation and maintenance of your installation

Preventive maintenance

Extending the lifetime of individual components

Increase reliability and availability

Ensure the long-term satisfaction of your customers

Tailor-made solutions, draw up timetables and develop recommendations at short notice

Professional advice for spare parts

Original spare parts

Tools and equipment

Warehouse containing over 23,000 spare parts

Commercial order, processing, logistics

Around-the-clock shipment

Transport and customs handling

with spare parts sales or

technical customer support

by Doppelmayr specialists with

suggestion for sanitation and

estimation of costs

with acceptance